Introduction to Product Flow Diagrams

Particularly within the framework of lean methodology, product flow diagrams serve as essential tools for visualizing and optimizing processes. These diagrams provide a clear representation of the steps involved in the production and delivery of a product, allowing project managers and lean practitioners to identify inefficiencies and streamline operations.

Definition of Product Flow Diagrams

A product flow diagram is a visual representation that outlines the sequence of activities involved in the production process, from the initial concept to the final delivery of the product. It typically includes various stages such as design, development, testing, and distribution, along with the flow of materials and information between these stages. By mapping out these processes, project managers can gain insights into how different components interact and where potential bottlenecks may occur.

Importance of Visualizing Product Flow for Project Success

Visualizing product flow is crucial for several reasons:

- Enhanced Clarity: By providing a graphical representation of the workflow, product flow diagrams help teams understand the entire process at a glance. This clarity is vital for effective communication among team members and stakeholders.

- Identification of Inefficiencies: These diagrams allow project managers to pinpoint areas where delays or redundancies occur, enabling them to implement targeted improvements. This is particularly important in lean environments, where the goal is to minimize waste and maximize value.

- Facilitating Continuous Improvement: Product flow diagrams are not static; they can be updated as processes evolve. This adaptability supports a culture of continuous improvement, which is a core principle of lean methodology.

Overview of How Product Flow Diagrams Fit into the Broader Context of Lean Methodology

Lean methodology emphasizes the elimination of waste and the enhancement of value for customers. Product flow diagrams align perfectly with these principles by:

- Supporting Value Stream Mapping: Product flow diagrams can be integrated into value stream mapping exercises, which are fundamental in lean practices. This integration helps teams visualize the flow of value through the production process and identify non-value-adding activities.

- Encouraging Cross-Functional Collaboration: By visualizing the entire product flow, these diagrams foster collaboration among different departments, such as design, manufacturing, and logistics. This collaboration is essential for ensuring that all aspects of the product lifecycle are aligned with lean principles.

- Driving Data-Driven Decisions: With a clear visual representation of the product flow, project managers can make informed decisions based on data rather than assumptions. This data-driven approach is crucial for optimizing processes and achieving lean objectives.

Product flow diagrams are invaluable tools in project management, particularly when aligned with lean methodology. They not only enhance understanding and communication but also drive continuous improvement and efficiency, ultimately contributing to project success.

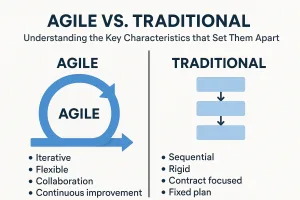

Understanding Lean Methodology

Lean methodology is a systematic approach to enhancing efficiency and effectiveness in various processes, particularly in product development and project management. It focuses on maximizing customer value while minimizing waste, thereby creating more value for customers with fewer resources. Here are the core principles and significance of lean methodology:

Definition of Lean Methodology and Its Core Principles

- Value: At the heart of lean methodology is the concept of value, which is defined from the customer’s perspective. Lean practices emphasize delivering products and services that meet customer needs and expectations, ensuring that every step in the process contributes to this value creation.

- Waste Reduction: Lean identifies seven types of waste (overproduction, waiting, transport, extra processing, inventory, motion, and defects) that do not add value to the customer. The goal is to eliminate these wastes to streamline processes and improve overall efficiency.

- Continuous Improvement (Kaizen): Lean promotes a culture of continuous improvement, encouraging teams to regularly assess and refine their processes. This principle fosters an environment where employees are empowered to suggest improvements, leading to incremental changes that enhance productivity and quality over time.

The Significance of Customer Value in Lean Practices

In lean methodology, customer value is paramount. Understanding what customers perceive as valuable allows organizations to focus their efforts on delivering those specific features and services. This customer-centric approach ensures that resources are allocated effectively, and efforts are concentrated on activities that enhance customer satisfaction. By prioritizing customer value, organizations can differentiate themselves in competitive markets and foster loyalty among their customer base.

Streamlining Processes and Enhancing Efficiency

Lean methodology aims to streamline processes by eliminating non-value-adding activities and optimizing workflows. This is achieved through various tools and techniques, such as:

- Value Stream Mapping: This tool helps visualize the flow of materials and information through the production process, identifying areas of waste and opportunities for improvement.

- Just-In-Time (JIT): JIT practices ensure that materials and products are produced only as needed, reducing inventory costs and minimizing waste.

- 5S Methodology: This organizational tool focuses on sorting, setting in order, shining, standardizing, and sustaining workplace organization, which contributes to improved efficiency and safety.

By implementing these lean principles, project managers can create product flow diagrams that not only illustrate the flow of products but also highlight areas for improvement, ensuring that the development process is as efficient and effective as possible. This alignment of lean principles with product flow diagrams enhances the overall project management strategy, leading to better outcomes and increased customer satisfaction.

Understanding lean methodology is crucial for lean practitioners and project managers aiming to enhance product development processes. By focusing on value, reducing waste, and fostering continuous improvement, organizations can create more efficient workflows that ultimately lead to greater customer satisfaction and business success.

The Role of Product Flow Diagrams in Lean Practices

Particularly within lean methodology, product flow diagrams serve as a vital tool for visualizing and optimizing processes. These diagrams not only enhance understanding but also facilitate the identification of inefficiencies and waste, which are central to lean principles. Here’s how product flow diagrams play a crucial role in lean practices:

Identifying Waste and Inefficiencies

- Visual Representation: Product flow diagrams provide a clear visual representation of the entire process, allowing teams to see each step involved in the production or service delivery. This visibility is essential for identifying areas where waste occurs, such as unnecessary steps, delays, or redundancies.

- Waste Types: By mapping out the flow of products or information, teams can pinpoint specific types of waste as defined by lean principles, including overproduction, waiting times, excess inventory, unnecessary motion, and defects. This identification is the first step toward eliminating waste and streamlining processes.

- Root Cause Analysis: The diagrams facilitate discussions around process inefficiencies, enabling teams to conduct root cause analyses. By understanding the underlying issues, project managers can implement targeted improvements that enhance overall efficiency.

Examples of Product Flow Diagrams in Lean Environments

- Manufacturing: In a manufacturing setting, product flow diagrams can illustrate the journey of a product from raw materials to finished goods. For instance, a diagram might show the flow of components through various stages of assembly, highlighting bottlenecks where delays occur.

- Service Industry: In service-oriented businesses, product flow diagrams can map customer interactions and service delivery processes. For example, a diagram could outline the steps a customer takes from initial inquiry to final service delivery, helping to identify areas for improvement in customer experience.

- Healthcare: In healthcare, product flow diagrams can be used to streamline patient care processes. By visualizing the flow of patients through various departments, healthcare providers can identify inefficiencies that may lead to longer wait times or reduced quality of care.

Connecting Product Flow Diagrams to Continuous Improvement Cycles

- Plan-Do-Check-Act (PDCA): Product flow diagrams are integral to the PDCA cycle, a cornerstone of lean methodology. During the Plan phase, teams can use these diagrams to design processes that minimize waste. In the Do phase, the processes are implemented, and the flow diagrams serve as a reference to ensure adherence to the planned steps.

- Check Phase: After implementation, the Check phase involves reviewing the product flow diagrams to assess performance against expected outcomes. Teams can analyze whether the changes have led to improvements in efficiency and waste reduction.

- Act Phase: Finally, in the Act phase, teams can make further adjustments based on the insights gained from the product flow diagrams. This iterative process fosters a culture of continuous improvement, where teams are encouraged to refine processes regularly.

Product flow diagrams are not merely tools for visualization; they are essential components of lean practices that drive efficiency and continuous improvement. By leveraging these diagrams, lean practitioners and project managers can enhance their understanding of processes, identify waste, and implement effective solutions that align with lean principles. This integration ultimately leads to more streamlined operations and improved outcomes across various industries.

Enhancing Product Flow Diagrams with Lean Principles

Product flow diagrams serve as essential tools for visualizing the processes involved in product development and delivery. By integrating lean principles into the creation and utilization of these diagrams, project managers and lean practitioners can significantly enhance their effectiveness. Here are some strategies and tips for leveraging lean thinking in product flow diagrams:

Tips for Utilizing Lean Thinking When Designing Product Flow Diagrams

- Focus on Value Stream Mapping: Begin by identifying the value stream associated with your product. This involves mapping out all the steps in the process, from raw materials to the final product, and distinguishing between value-adding and non-value-adding activities. Lean thinking emphasizes eliminating waste, so ensure that your diagram highlights areas where improvements can be made to streamline processes.

- Simplify and Standardize: Lean principles advocate for simplicity and standardization. When designing your product flow diagram, aim for clarity by using standardized symbols and terminology. This not only makes the diagram easier to understand but also facilitates communication among team members and stakeholders.

- Iterative Design: Embrace an iterative approach to designing your product flow diagrams. Lean methodology encourages continuous improvement, so regularly revisit and refine your diagrams based on feedback and new insights. This iterative process helps ensure that the diagrams remain relevant and effective over time.

Strategies for Involving Cross-Functional Teams in Diagram Development

- Collaborative Workshops: Organize workshops that bring together cross-functional teams, including representatives from engineering, marketing, sales, and customer service. These sessions can foster collaboration and ensure that diverse perspectives are considered in the development of the product flow diagram. Engaging various stakeholders helps to create a more comprehensive and accurate representation of the product flow.

- Utilize Visual Management Techniques: Incorporate visual management techniques, such as sticky notes or digital collaboration tools, to facilitate brainstorming and discussion during the diagram development process. This approach encourages active participation and allows team members to contribute their insights and expertise, leading to a more robust product flow diagram.

- Establish Clear Roles and Responsibilities: Clearly define the roles and responsibilities of each team member involved in the diagram development. This clarity helps streamline the process and ensures that everyone understands their contributions to the final product flow diagram.

Methods to Ensure Diagrams Reflect Real-Time Data and Customer Feedback

- Integrate Real-Time Data Sources: Leverage technology to integrate real-time data sources into your product flow diagrams. This could involve using software tools that allow for live updates based on production metrics, inventory levels, or customer feedback. By incorporating real-time data, your diagrams will provide a more accurate representation of the current state of the product flow.

- Feedback Loops: Establish feedback loops with customers and stakeholders to gather insights on their experiences and expectations. Incorporate this feedback into your product flow diagrams to ensure they reflect the needs and preferences of the end-users. This customer-centric approach aligns with lean principles by focusing on delivering value.

- Regular Review and Adaptation: Schedule regular reviews of your product flow diagrams to assess their relevance and effectiveness. Use these reviews as opportunities to adapt the diagrams based on new data, changing market conditions, or evolving customer needs. This ongoing adaptation process is a core tenet of lean methodology, ensuring that your diagrams remain aligned with the principles of continuous improvement.

By integrating these lean principles into the creation and utilization of product flow diagrams, project managers and lean practitioners can enhance their effectiveness, foster collaboration, and ensure that the diagrams serve as valuable tools for driving efficiency and delivering customer value.

Challenges and Solutions in Creating Product Flow Diagrams under Lean

Creating product flow diagrams (PFDs) is a critical task in project management, particularly within the framework of lean methodology. While PFDs serve as valuable tools for visualizing processes and identifying areas for improvement, several challenges can arise when attempting to align these diagrams with lean principles. Below, we explore common obstacles, strategies for overcoming resistance to change, and tools that can facilitate the creation of effective product flow diagrams.

Common Obstacles in Aligning Product Flow Diagrams with Lean Principles

- Complexity of Processes: Many organizations have intricate processes that can be difficult to represent accurately in a PFD. This complexity can lead to oversimplification or misrepresentation of workflows, which undermines the lean goal of eliminating waste and enhancing efficiency.

- Lack of Standardization: Without standardized symbols and notations, teams may create PFDs that are inconsistent and difficult to interpret. This inconsistency can hinder communication and collaboration among team members, making it challenging to implement lean practices effectively.

- Resistance to Change: Team members may be accustomed to existing processes and hesitant to adopt new methodologies. This resistance can manifest as reluctance to engage in the creation of PFDs or to embrace the changes that lean principles advocate.

- Insufficient Training: A lack of understanding of both lean principles and the technical aspects of creating PFDs can impede progress. Team members may struggle to identify value-added activities versus non-value-added activities, which is essential for effective lean implementation.

Strategies for Overcoming Resistance to Change within Teams

- Engage Stakeholders Early: Involve team members and stakeholders in the initial stages of creating product flow diagrams. By soliciting their input and addressing their concerns, you can foster a sense of ownership and reduce resistance.

- Provide Training and Resources: Offer training sessions on lean principles and the importance of PFDs. Providing resources such as templates and examples can help team members feel more confident in their ability to contribute to the diagrams.

- Communicate the Benefits: Clearly articulate the advantages of using PFDs within a lean framework, such as improved efficiency, reduced waste, and enhanced collaboration. Highlighting these benefits can motivate team members to embrace the changes.

- Implement Incremental Changes: Rather than attempting to overhaul processes all at once, introduce changes gradually. This approach allows team members to adapt to new practices without feeling overwhelmed.

Tools and Resources that Can Facilitate the Creation of Effective Diagrams

- Diagramming Software: Tools like Lucidchart, Microsoft Visio, and Miro provide user-friendly interfaces for creating product flow diagrams. These platforms often include templates and symbols that align with lean principles, making it easier for teams to visualize processes.

- Lean Management Software: Solutions such as LeanKit and Kanbanize offer features specifically designed for lean project management. These tools can help teams track progress, identify bottlenecks, and create flow diagrams that reflect lean methodologies.

- Collaboration Platforms: Utilizing platforms like Trello or Asana can enhance team collaboration during the diagram creation process. These tools allow for real-time feedback and updates, ensuring that all team members are aligned and engaged.

- Training Resources: Online courses and workshops focused on lean methodologies and process mapping can equip team members with the necessary skills to create effective product flow diagrams. Websites like Coursera and LinkedIn Learning offer valuable content in this area.

By addressing these challenges and implementing effective strategies, project managers and lean practitioners can enhance the creation of product flow diagrams, ultimately leading to more efficient processes and successful project outcomes. Embracing lean principles in the development of PFDs not only streamlines workflows but also fosters a culture of continuous improvement within teams.

Conclusion: The Synergy of Product Flow Diagrams and Lean Methodology

The integration of product flow diagrams with lean methodology presents a powerful opportunity for enhancing efficiency and effectiveness. By visualizing the flow of products and processes, project managers can identify bottlenecks, streamline operations, and ultimately deliver greater value to customers. Here are some key insights that highlight the benefits of this integration:

- Enhanced Clarity and Communication: Product flow diagrams serve as a visual tool that simplifies complex processes, making it easier for teams to understand workflows and identify areas for improvement. This clarity is essential in lean environments where communication and collaboration are paramount.

- Identification of Waste: Lean principles focus on eliminating waste in all forms. By utilizing product flow diagrams, practitioners can pinpoint non-value-adding activities within the workflow, allowing for targeted interventions that enhance productivity and reduce costs.

- Facilitation of Continuous Improvement: The iterative nature of lean methodology aligns perfectly with the dynamic nature of product flow diagrams. As teams continuously refine their processes, these diagrams can be updated to reflect changes, fostering a culture of ongoing improvement and adaptability.

- Empowerment of Teams: Engaging team members in the creation and analysis of product flow diagrams encourages ownership and accountability. This empowerment is a core tenet of lean thinking, as it motivates individuals to contribute to process enhancements actively.

As lean practitioners and project managers, it is crucial to embrace these insights and apply them in your work. The intersection of product flow diagrams and lean principles not only enhances project outcomes but also cultivates a mindset geared towards efficiency and quality.

Find out more about Shaun Stoltz https://www.shaunstoltz.com/about/.

This post was written by an AI and reviewed/edited by a human.